Home > Our Company > News & Events

News & Events

ADDEV Materials Healthcare, a market leader in material converting and clean room manufacturing of disposable medical devices and engineered adhesive components, will be displaying at the MD&M Show in Anaheim Feb 3-5, 2026, at booth 2476. ADDEV Materials Healthcare is an ISO13845:2016 certified, FDA registered, and cGMP compliant contract manufacturer

Medical wearables have rapidly moved from niche innovations to everyday healthcare tools that support continuous monitoring, drug delivery, diagnostics, and personal wellness. As device developers push for longer wear times, more complex sensing capabilities, and higher patient comfort, the materials behind these solutions have become just as critical as the

At ADDEV Materials Healthcare, we specialize in converting high-performance foams into application-ready solutions through advanced lamination and precision manufacturing. By combining world-class foams with specialized adhesives, we create customized medical foam tapes that enhance comfort, improve reliability, and support patient safety. High-Performance Foams for Healthcare We convert a wide range

Foams in Healthcare: Why They Matter Today and Where They’re Headed Tomorrow In medical devices, every component serves a purpose, and foams are no exception. While often hidden from view, they play an essential role in sealing, protecting, cushioning, and enhancing comfort. Without them, devices would be noisier, less reliable,

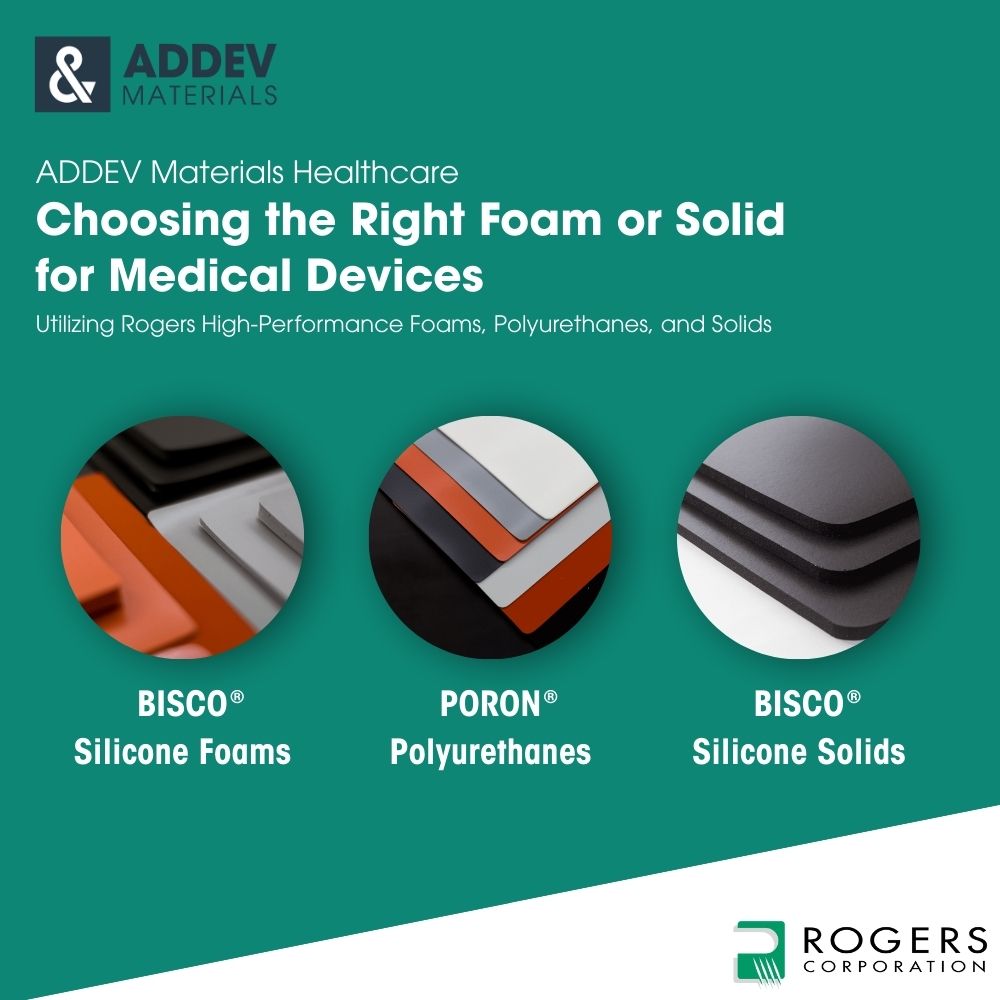

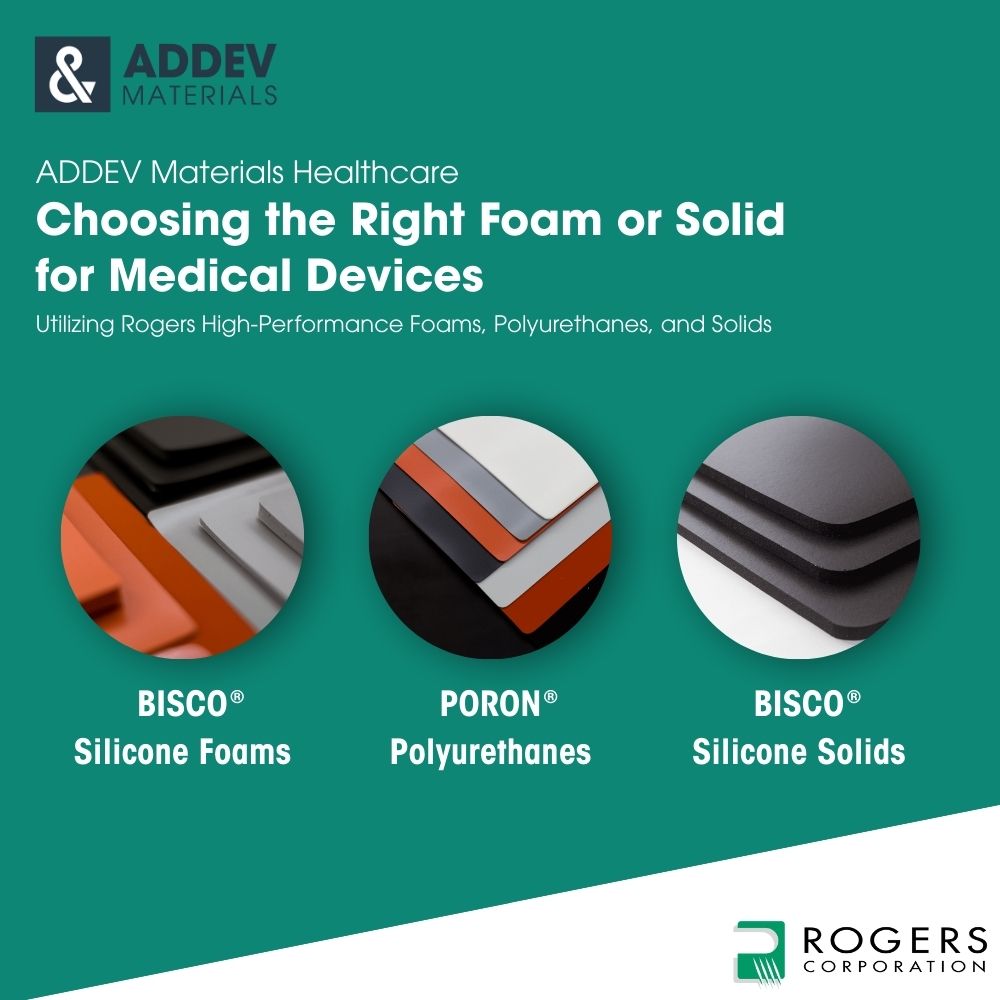

In medical device design, the smallest material choice can make the biggest difference. A seal that doesn’t hold, a cushion that breaks down, or a gasket that degrades under sterilization can compromise performance and patient safety. That’s why ADDEV Healthcare partners with Rogers Corporation, a leader in advanced technical materials,

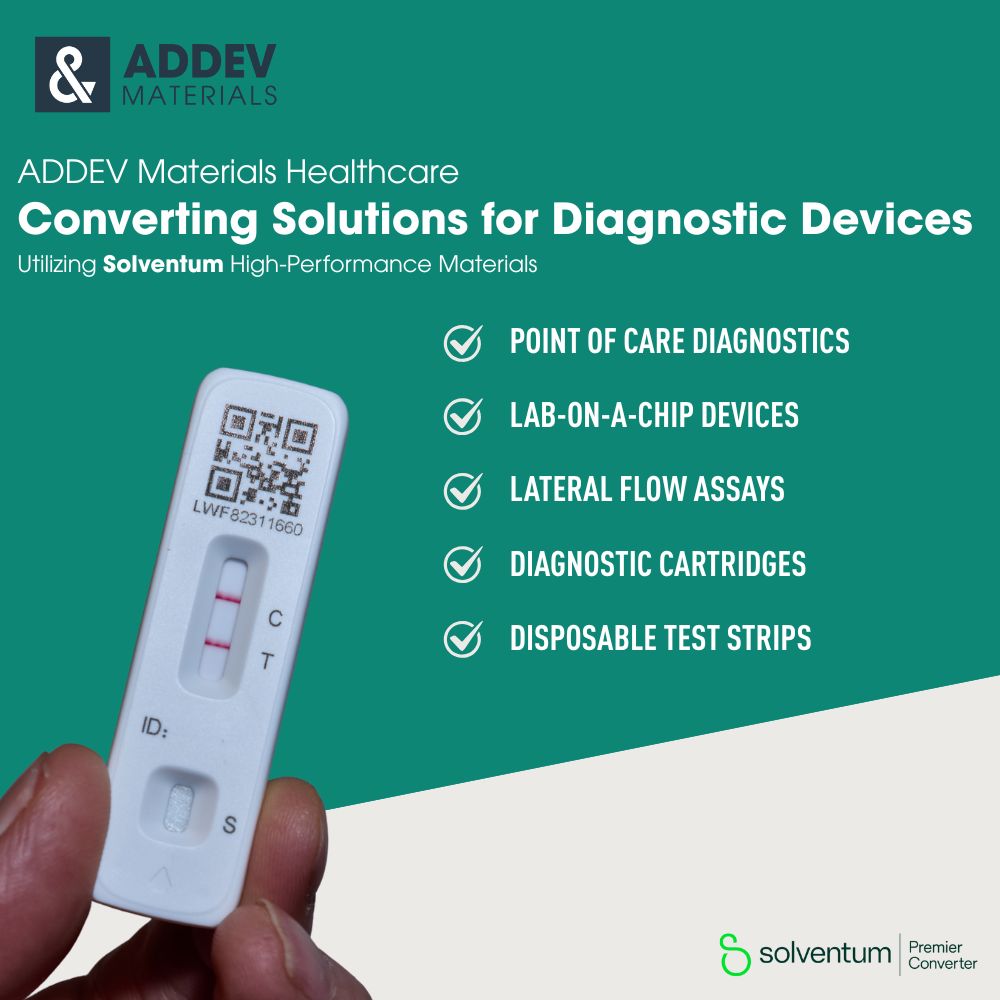

As the demand for rapid, accurate diagnostics and miniaturized lab-on-chip platforms continues to grow, so does the need for engineered materials that are precise, biocompatible, and high-performance. Microfluidic devices used in applications like molecular diagnostics, point-of-care testing, and lateral flow assays, rely on highly specialized films to function reliably in

The adhesive interface is a vital part of any wearable medical device. If it fails, the device can shift or detach, compromising performance and user safety. The skin is a complex, living organ that varies greatly from person to person—and even from one part of the body to another. Because

Wearable devices like continuous glucose monitors (CGMs) and insulin patch pumps are reshaping diabetes care by delivering real-time glucose readings and precise insulin dosing. Their overall effectiveness relies not only on advanced sensor technology but also on the reliability of the adhesive that keepS them in place. For these devices

In today’s rapidly evolving healthcare industry, having the right partner to convert flexible materials into high-performance components is crucial. At ADDEV Materials Healthcare, we specialize in precision printing and converting, offering cutting-edge solutions for the healthcare industry. With our state-of-the-art capabilities and commitment to quality, we help bring innovative disposable

At ADDEV Materials Healthcare, we understand that developing new disposable medical devices is a complex yet essential process for improving patient outcomes and advancing healthcare technology. As a leader in disposable medical device manufacturing, we offer comprehensive product development support, from initial concept to final production, while ensuring the highest standards of

ADDEV Materials Healthcare, a market leader in material converting and clean room manufacturing of disposable medical devices and engineered adhesive components, will be displaying at the MD&M Show in Anaheim Feb 3-5, 2026, at booth 2476. ADDEV Materials Healthcare is an ISO13845:2016 certified, FDA registered, and cGMP compliant contract manufacturer

Medical wearables have rapidly moved from niche innovations to everyday healthcare tools that support continuous monitoring, drug delivery, diagnostics, and personal wellness. As device developers push for longer wear times, more complex sensing capabilities, and higher patient comfort, the materials behind these solutions have become just as critical as the

At ADDEV Materials Healthcare, we specialize in converting high-performance foams into application-ready solutions through advanced lamination and precision manufacturing. By combining world-class foams with specialized adhesives, we create customized medical foam tapes that enhance comfort, improve reliability, and support patient safety. High-Performance Foams for Healthcare We convert a wide range

Foams in Healthcare: Why They Matter Today and Where They’re Headed Tomorrow In medical devices, every component serves a purpose, and foams are no exception. While often hidden from view, they play an essential role in sealing, protecting, cushioning, and enhancing comfort. Without them, devices would be noisier, less reliable,

In medical device design, the smallest material choice can make the biggest difference. A seal that doesn’t hold, a cushion that breaks down, or a gasket that degrades under sterilization can compromise performance and patient safety. That’s why ADDEV Healthcare partners with Rogers Corporation, a leader in advanced technical materials,

As the demand for rapid, accurate diagnostics and miniaturized lab-on-chip platforms continues to grow, so does the need for engineered materials that are precise, biocompatible, and high-performance. Microfluidic devices used in applications like molecular diagnostics, point-of-care testing, and lateral flow assays, rely on highly specialized films to function reliably in

The adhesive interface is a vital part of any wearable medical device. If it fails, the device can shift or detach, compromising performance and user safety. The skin is a complex, living organ that varies greatly from person to person—and even from one part of the body to another. Because

Wearable devices like continuous glucose monitors (CGMs) and insulin patch pumps are reshaping diabetes care by delivering real-time glucose readings and precise insulin dosing. Their overall effectiveness relies not only on advanced sensor technology but also on the reliability of the adhesive that keepS them in place. For these devices

In today’s rapidly evolving healthcare industry, having the right partner to convert flexible materials into high-performance components is crucial. At ADDEV Materials Healthcare, we specialize in precision printing and converting, offering cutting-edge solutions for the healthcare industry. With our state-of-the-art capabilities and commitment to quality, we help bring innovative disposable

At ADDEV Materials Healthcare, we understand that developing new disposable medical devices is a complex yet essential process for improving patient outcomes and advancing healthcare technology. As a leader in disposable medical device manufacturing, we offer comprehensive product development support, from initial concept to final production, while ensuring the highest standards of