Medical wearables have rapidly moved from niche innovations to everyday healthcare tools that support continuous monitoring, drug delivery, diagnostics, and personal wellness. As device developers push for longer wear times, more complex sensing capabilities, and higher patient comfort, the materials behind these solutions have become just as critical as the technology they carry.

At the center of this innovation are advanced stick-to-skin materials, engineered adhesives, films, and nonwovens that enable reliable device attachment without compromising skin integrity. These materials must balance performance, biocompatibility, durability, and converting efficiency, often under demanding regulatory expectations.

ADDEV Materials Healthcare, in collaboration with Avery Dennison Medical, supports device developers with high-performance adhesive technologies, engineered films, and cleanroom-based converting services tailored specifically for wearable medical devices. Together, we help bridge the gap between material science and manufacturable product design.

Below, we highlight three Avery Dennison solutions, each engineered for different wearable needs, and how they enable next-generation disposable medical device performance.

Avery Dennison MED 5744

Long-Term Wear, High Breathability, and Comfort

For 14–28 day wear devices, achieving the right balance of adhesion, breathability, and comfort is essential. Avery Dennison MED 5744 is a single-sided long-term medical tape designed specifically for extended wear applications such as:

- Continuous glucose monitors

- Insulin pumps

- Activity trackers

- ECG monitoring patches

- Other mobile health and wellness devices

MED 5744 features an acrylic-based adhesive coated onto a soft, conformable polyester nonwoven. The nonwoven structure allows heat and moisture to escape, reducing skin maceration during long-term use. At the same time, its extended wear performance maintains device stability, even for active users.

For device engineers, MED 5744 offers a versatile, breathable platform that converts cleanly and integrates well into multilayer device constructions.

Inquire about this material on the Material Finder

Avery Dennison MED 5500SI

Soft Silicone Comfort for Sensitive Skin and Repositioning

Some wearable applications require gentle adhesion, repositionability, and compatibility with wound care or skin-sensitive environments. The Avery Dennison MED 5500SI is engineered precisely for these needs. This single-coated, transparent polyurethane film uses a soft silicone adhesive to provide:

- Gentle adhesion suitable for fragile or compromised skin

- A smooth, conformable film for comfort during wear

- Repositioning capability during application

- Compatibility with multi-layer wound dressings and stick-to-skin wearables

Common applications include:

- Silicone wound contact layers

- Patient monitoring patches

- Wearable devices requiring low-trauma removal

- Ostomy flanges

- Scar treatment products

With its dual-liner construction, a blue LDPE release liner and a white paper carrier, MED 5500SI enables controlled processing, making it converter-friendly for complex device designs.

Inquire about this material on the Material Finder

Avery Dennison MED 3046

Secure Device Mounting with Dual-Sided Adhesion

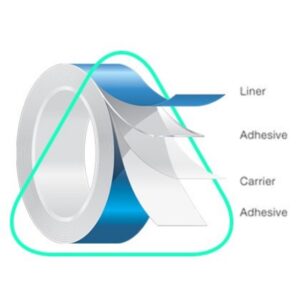

Wearable devices with rigid housing, such as drug delivery pods, electronic sensors, and diagnostic modules, require a strong mechanical interface between the device and the patient’s skin. Avery Dennison MED 3046 delivers a durable, dual-sided bonding solution built for multi-day wear.

Built with a conformable polyurethane film and acrylic-based adhesives on both sides, MED 3046 is engineered to:

- Bond securely to polyester (PET) nonwovens on one side

- Adhere to rigid device housings on the other

- Support wear times of up to 21 days

- Offer design and converting flexibility through its heavy-weight liner

This makes MED 3046 a strong choice for device assemblies requiring stability, durability, and clean converting performance.

Shaping the Future of Wearable Healthcare… Together

Avery Dennison’s MED 5744, MED 5500SI, and MED 3046 represent three distinct approaches to wearable design, each solving a different challenge within the market:

- Breathable extended wear (MED 5744)

- Gentle silicone comfort and repositionability (MED 5500SI)

- Strong dual-sided mounting for rigid devices (MED 3046)

From continuous monitoring and drug delivery to next-generation diagnostic platforms, the future of medical wearables depends on high-performance stick-to-skin materials that are safe, comfortable, and reliable.

ADDEV Materials Healthcare brings these advanced materials to life through certified cleanroom converting, precision die-cutting, multilayer lamination, and device-ready formatting that protect material integrity from prototype through production. Our ISO 13485–certified and FDA-registered operations ensure that breathable long-term adhesives, gentle silicone solutions, and dual-sided mounting tapes are converted with the consistency, cleanliness, and dimensional accuracy wearable devices demand. By combining Avery Dennison’s high-performance stick-to-skin materials with ADDEV’s engineered manufacturing support, we help device developers accelerate commercialization and deliver wearable technologies that stay secure, feel comfortable, and perform reliably on the patient.

Why Choose ADDEV Materials for Two-Sided Medical Tape Converting?

With decades of converting expertise and a certified ISO 13485 and FDA-registered infrastructure, ADDEV Materials Healthcare brings unmatched value:

- Precision Converting – Rotary, flatbed, and laser die-cutting; slitting; spooling; lamination; cleanroom manufacturing

- Customized Solutions – Tailoring double medical adhesive tape constructs to your design and performance requirements

- Material Expertise – Preferred converter status with leading suppliers like DermaMed, Solventum, Adhesive Research, and Avery Dennison

- Contract Manufacturing & Support – Custom assembly, printing, packaging, and full conversion services to accelerate your time to market.