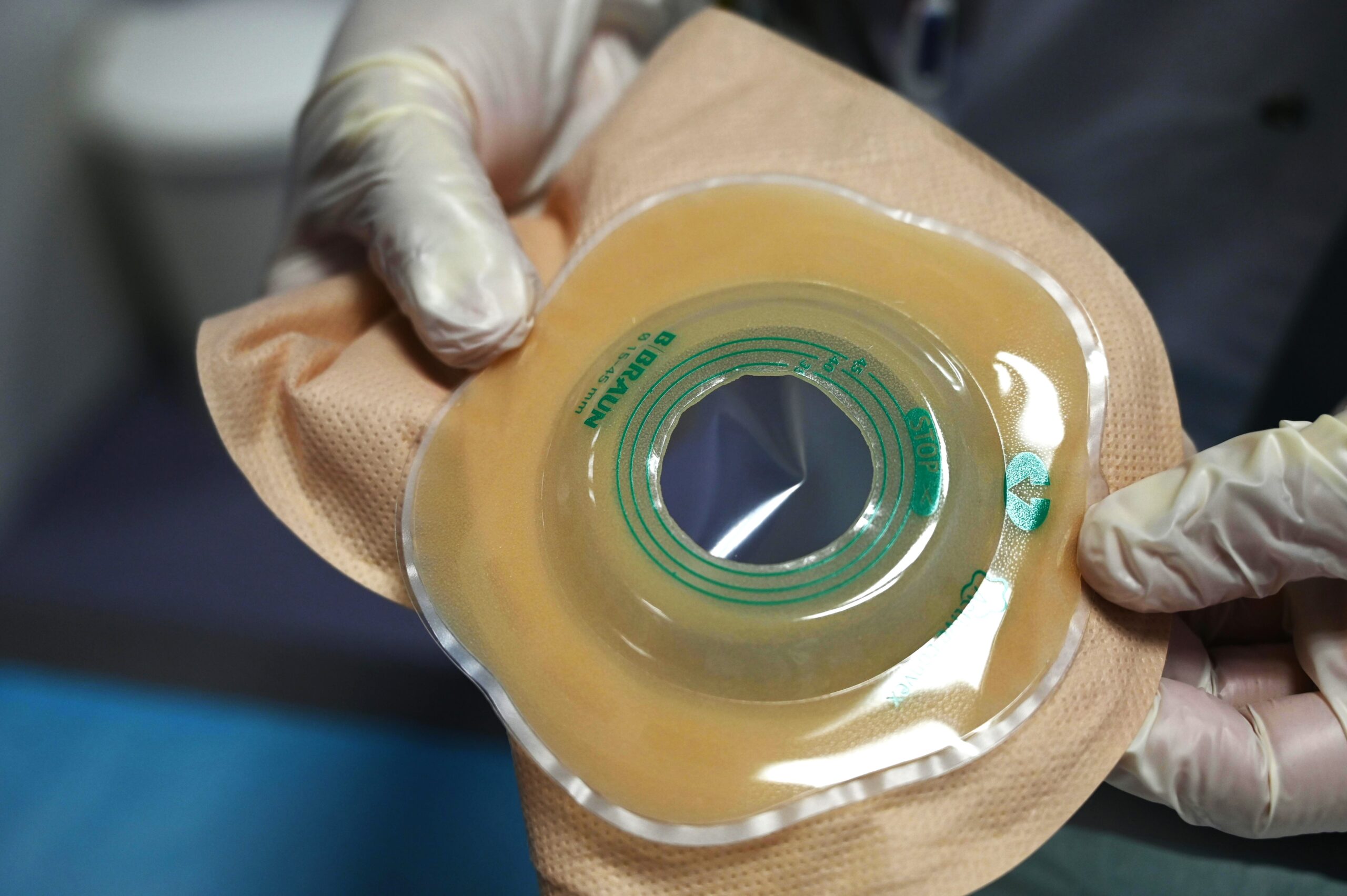

Ostomy

Medical-grade foams are essential in a wide range of healthcare products, offering comfort, protection, absorption, and performance in both skin-contact and device-related applications. These engineered foams are designed to meet the rigorous requirements of medical environments—from wound care and wearable devices to surgical components and medical equipment.

In healthcare applications, foams must do more than provide structure—they must be, conformable, breathable, and reliable under critical use conditions. Medical foams are available in open-cell or closed-cell formats, offering a variety of performance characteristics such as moisture management, cushioning, and fluid absorption.

Medical films are used in countless applications where performance, precision, and patient safety are non-negotiable. Some common uses include:

Medical foams serve both functional and comfort-driven roles in a variety of healthcare products:

At AMH, we convert and supply a range of medical-grade foams that meet diverse functional and regulatory needs:

With expertise in cleanroom converting and supplier partnerships with industry leaders like Rogers, we help you integrate the right foam into your medical product—whether it’s a patient-facing dressing or a high-precision diagnostic assembly.

Backed by decades of experience in medical materials and precision converting, we partner with you through every stage of device development. From concept to cleanroom production, our capabilities are built to meet the demands of healthcare innovation.

As a preferred converter for leading material suppliers, we offer trusted access to high-performance materials and the technical expertise to help you get the most from them.

Can’t find the foam you are looking for? Check out our material finder to find the perfect foam for your next medical device project.

Call us 262.255.6150 or send a message to info.amh@addevmaterials.com TODAY to connect with a specialist about your custom product.