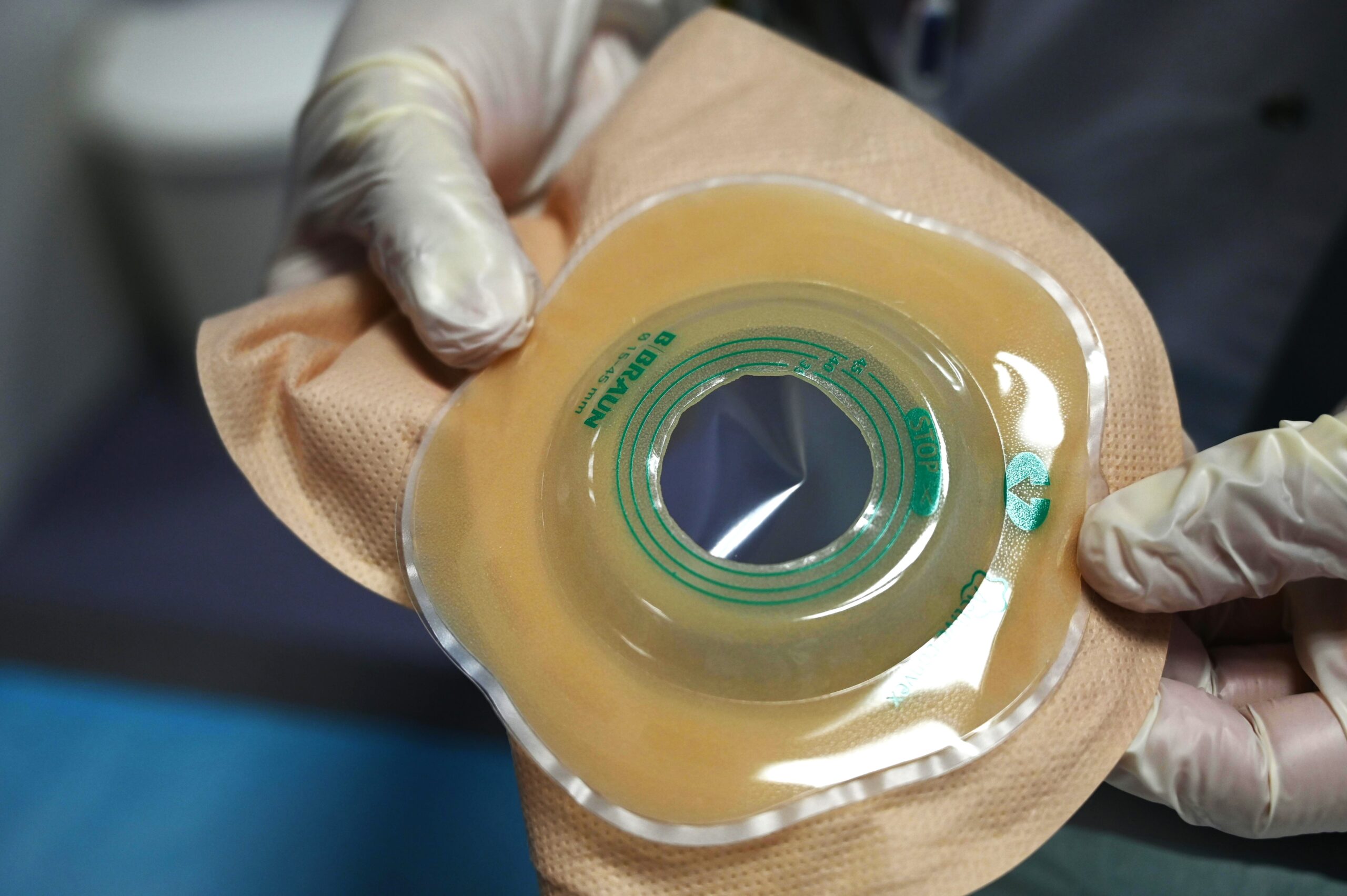

Ostomy

Medical films play a critical role across a wide range of healthcare and life science applications—from wound care dressings to microfluidic diagnostic devices. These engineered films are designed to meet strict performance, regulatory, and manufacturing requirements.

In medical settings, materials must do more than perform—they must do so reliably, consistently, and safely under critical conditions. Medical films are developed with these demands in mind. Whether used in skin-contact devices, sterile packaging, or complex diagnostic platforms, these films must meet a range of specifications, including biocompatibility, sterilizability, breathability, chemical resistance, and precise thickness control. Compatibility with cleanroom environments and high-speed processing also makes film materials ideal for scalable manufacturing.

Medical films are used in countless applications where performance, precision, and patient safety are non-negotiable. Some common uses include:

We supply and convert a wide selection of films tailored to meet specific functional, chemical, and regulatory demands. These include:

Backed by decades of experience in medical materials and precision converting, we partner with you through every stage of device development. From concept to cleanroom production, our capabilities are built to meet the demands of healthcare innovation.

As a preferred converter for leading material suppliers, we offer trusted access to high-performance materials and the technical expertise to help you get the most from them.

Can’t find the film you are looking for? Check out our material finder to find the perfect film for your next medical device project.

Call us 262.255.6150 or send a message to info.amh@addevmaterials.com TODAY to connect with a specialist about your custom product.